Print ‘n Press

An inviting mechanical device that promotes limitless graphic creativity

Print & Press was my first solo project for Industrial Design. The project was called “Craft Stories, Promoting diversity“. The project is about how in past decades crafts have fallen out of favour and became overlooked. Many people don’t even think about how their products are made anymore, and may even forget how they are made at all.

A big personal interest of mine is graphical design, but it came to me that the way a design is printed has never received my full interest. The more I thought about it, the more I realised that it was strange that the process, which is digital, and the medium, which is physical, are separated immensely.

I decided to find out what traditional printing techniques have to offer us today and how they could reinforce the overall process of creating graphic work. How can anyone print without having any restrictions, without having to spend hundreds or thousands of Euros?

Print and Press is designed to give back the process to graphic designers. Nowadays when a graphic design is made, this is done on a computer. Afterwards it has to be made physical someway and a printer is usually the go to option because it is available and cheap. What is often forgotten however is how limiting using a printer is (limited paper options, nearly non-existent ink choices).

Print and Press aims to let anyone experiment with and iterate their graphic designs on any medium: wood, paper, leather, shirts, functionally everything.

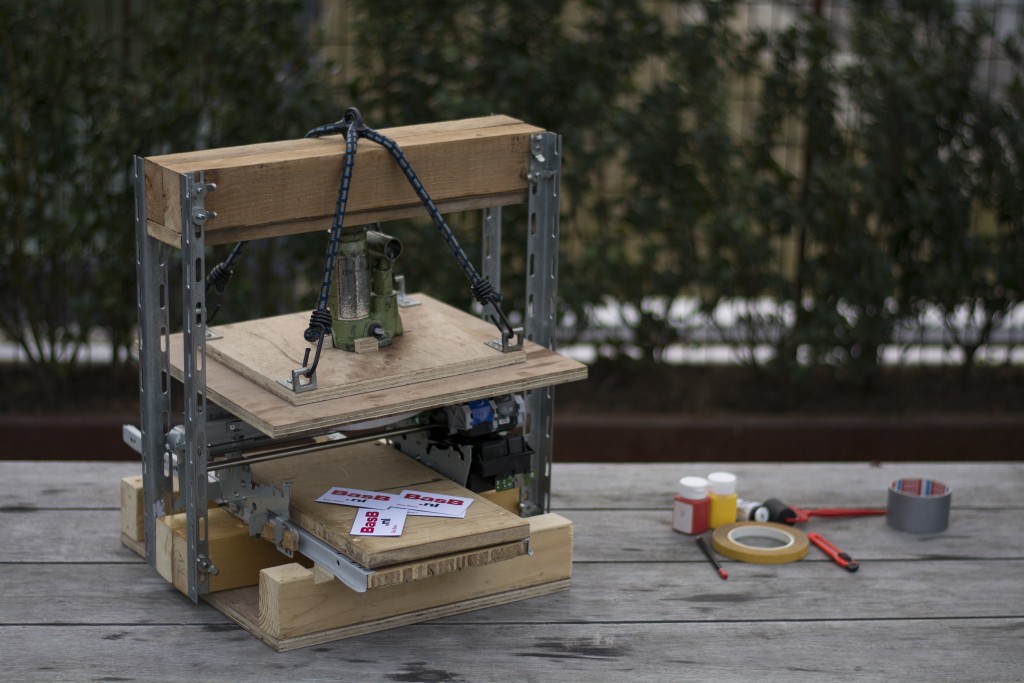

I talked to some professional old and new style printers to really understand what has changed in the printing business, what they miss but also what has improved. Based on this i decided my device had to consist out of two parts: an old school press and a new style printer.

The catch was that the press could not be archaic, using hunderds upon hundreds of lead letters was out of the question. After inquiry I decided to incorporate lasercutting for this purpose, users would be able to lasercut the letters and basic shapes they need out of acrylic plates, which are very suitable for printing for they are hard and do not react with the ink.

Finally, the printer part of the device could not be as limited as modern printers. A flatbed printer was the way to go, though traditionally these would cost thousands of euros, I decided to adapt a regular, cheap printer for this purpose.

By combining these two devices the Print & Press is made. The press allows users wide ink choices, deep pressing, punching and many organic effects, while the printer allows easy photo or text printing on any material.

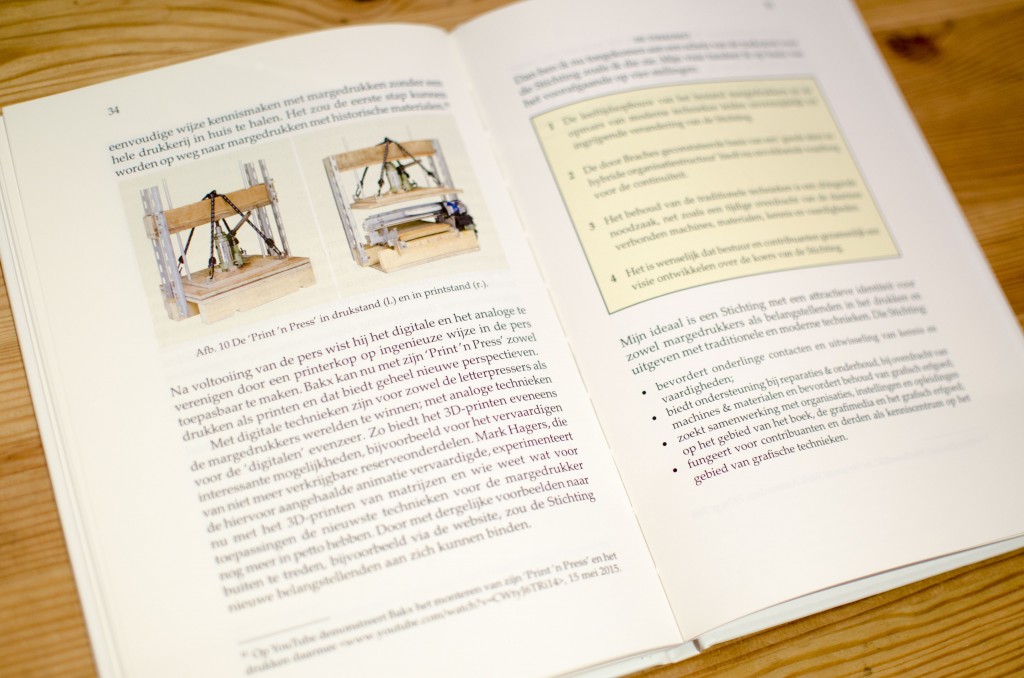

The crown on this project is that it got picked up by Gerard Post van der Molen. A classic printer based in Ruurlo, where he runs pressroom “de Ammoniet”. Gerard was working on the 24th “Bert van Selm-lezing”, a yearly reading commemorating book historian Bert van Selm. It is given yearly at and for the University of Leiden. The reading was about marginal printing (small-scale artisanal traditional book pressing) and the 40th birthday of the biggest dutch foundation relating to this; Stichting Drukwerk in de Marge.

Gerard worked the link the Print ‘n Press makes between digital and analogue into his reading on the 1st of September 2015 in Leiden. Above all, an early design sketch of Print ‘n Press made it onto the front cover of the beautiful limited hardcover publication that went with the reading!